Pterodactyl

ultralight, Pterodactyl single place part 103 legal

ultralight aircraft, Ultralight News

newsmagazine.

|

Ultralight News is a directory of aircraft that generally fit

into what are described as ultralight aircraft, advanced ultralight

aircraft,

ultralite aircraft, ultralight planes, experimental

aircraft, amateur built aircraft, or homebuilt

or kit built aircraft in the United States and Canada. These include weight shift aircraft, more commonly known as microlight trikes, powered parachutes, and powered para-gliders.

This site has been set up to work with

Internet Explorer, it is possible Windows Media Files may not play in

other browsers. |

|

|

|

|

|

|

Pterodactyl

single place part 103 legal

ultralight, ultra lite aircraft, amateur built, experimental,

homebuilt aircraft.

|

|

This article is reprinted courtesy of the Transport Canada Aviation Safety Letter.

It appeared in the ASL issue 4/2003 on page 11

COPA Corner:

Why Do a

Walk Around?

by Adam Hunt,

Canadian Owners and Pilots Association (COPA)

I recently received a question from some low time pilots. They

reported several instances where experienced pilots have jumped

into their plane and flown away without doing a pre-flight

inspection. They wondered if pre-flights are something worth

doing, or if they are just exercises for student pilots? |

Of course most

of the time the aircraft has sat, untouched,

since its last flight. But an oil leak may

have developed, or someone may have done

some "hangar rash" to the plane.

In some cases, a thief may have siphoned out

all the fuel, except a few litres. That

could be a surprise on take-off. Pilots have

taken off with external control locks in

place, or with concrete blocks tied to the

tail. It is very important to do a complete

pre-flight inspection before every flight.

One of the most important times to do a

careful pre-flight inspection is when the

aircraft has been through maintenance or

when it has just been reassembled after

being transported. This story shows just how

wrong things can go, for lack of a

pre-flight inspection. |

|

|

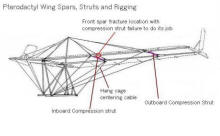

The worst thing is that the same accident has been repeated more

than once, always with the same fatal results. Even though

this story involves a particular aircraft type, the Pterodactyl

Ascender ultralight aircraft, the lesson learned is universal.

These cartop transportable aircraft are often kept at home and

then assembled prior to flight at the airport. There were original

manufacturer's investigations following up the official

investigations of several early 1980s accidents where a leading

edge spar failed in flight, with no other aircraft components

failing. In all cases the results were fatal.

The official investigations listed these accidents as "Undetermined,"

but the follow-up factory investigations found the answers. In

each case the spar failed just outboard of the inboard spar sleeve

junction, where the inner set of rigging cables joins the spar.

The spar failed upwards and twisted as it failed, giving a very

distinctive signature to the failure.

These spar failures all had the same signatures and the same

causes - the inboard compression strut had failed to do its job.

Each wing has two compression struts.

The compression struts are

designed to keep the front and rear tubular spars apart and also

to take the wing's inter-spar compressional forces. Without the

inboard compression strut in place, both spars will move together

until one breaks. The rear spar is prevented from moving forward

by the hang cage centering cable, so the front spar is the one

that fails.

There are several reasons why the compression strut can fail to do

its job. The compression strut mounting brackets, the bolts or the

compression strut itself could fail. There are no

recorded

instances of the failure of any of these parts. In all accidents

investigated, the parts mentioned above were undamaged. The most

likely reason for these accidents is that the compression strut

was not secured during assembly

of the aircraft.

Pterodactyl Ascender ultralights are designed for quick

disassembly

and reassembly and the compression strut is provided

in two parts, joined by a sliding bolt lock.

If the two

compression strut parts are not connected during assembly, or the

bolt lock is not slid into place, the result will be a spar

failure in flight. The requirement to check this item is clearly

outlined in the Pterodactyl Builder's Manual.

The Pterodactyl wing sail is

provided with four zippers for just this pre-flight item.

The key defence against these kinds of spar failures is a good

pre-flight inspection. Special care should be taken to inspect

these after the aircraft has been reassembled or has undergone

maintenance affecting the compression strut area.

Your aircraft doesn't have to have "quick disconnect" style

compression struts to have critical pre-flight inspection items.

All aircraft have items related to control locks, tie-downs, fuel,

oil and other fluids plus many damage-sensitive, structural and

control-related areas that must be inspected before each flight.

Do you really need a pre-flight inspection before you fly any type

of aircraft? You bet your life you do!

From ASL 4/2003 Page 11 |

Pterodactyl single place part 103

legal ultralight aircraft

|

|

Empty Weight: |

254 lbs. |

|

Gross Weight: |

535 lbs. |

|

Wing Span: |

33 ft. |

|

Wing Area: |

173 sq. ft. |

|

Engine:

|

430 Cuyuna |

|

Cruise Speed: |

55 mph. |

|

Stall Speed: |

25 mph. |

|

VNE: |

85 mph. |

|

Construction: |

bolt together tube and dacron fabric |

|

Building time: |

100 hrs. |

|

|

|

Pterodactyl single place part 103 legal

ultralight aircraft

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ultralight News Web Magazine.

You may link to these pages or print

them out for your own personal use.

No part of this

publication may be copied or distributed, transmitted, transcribed,

stored in a retrieval system, or translated into any human or computer

language, in any form or by any means, electronic, mechanical,

manual, or otherwise, without the written permission of UltralightNews.

By copying or paraphrasing the intellectual

property on this site, you're automatically signing a binding contract

and agreeing to be billed $10,000 payable immediately. Copyright UltralightNews Email

|