Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem

Ipsum has been the industry's standard dummy text ever since the 1500s, when an

unknown printer took a galley of type and scrambled it to make a type specimen

book. It has survived not only five centuries, but also the leap into electronic

typesetting, remaining essentially unchanged.

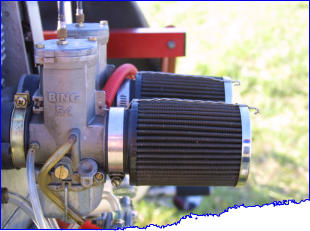

Troubleshooting the Beaver family of ultralight aircraft - Bing 54 carb updates.

UltralightNews.com

Lorem Ipsum is simply dummy text

of the printing and typesetting

industry. Lorem Ipsum has been the

industry's standard dummy text ever

since the 1500s, when an unknown

printer took a galley of type and

scrambled it to make a type

specimen book. It has survived not

only five centuries, but also the leap

into electronic typesetting, remaining essentially

unchanged.

Beaver, Beaver ultralight aircraft, Beaver RX 35 ultralight

aircraft, Beaver RX 550 ultralight trainer troubleshooting report.

Another reported problem by Beaver owners has been with the airfilter coming off

the carburetor in flight and striking the prop. This has resulted in several fatalities!

To help prevent this, it is suggested that a small hole be drilled in the back of the

carb and front of the airfilter and that these holes be used to safety wire the

airfilter to the carburetor.

Another update has the two separate vent holes found on the sides of the carbs

being replaced by one line with vent holes in the bottom. This prevents improper

fuel to air mixture in the carburetor.

Owners have also reported their throttle cables slipping in the retaining clamp at

the throttle handle junction. In Canada many owners have reported their throttle

cables freezing during winter operations.

Some owners have changed the position of their ignition switches after they have

applied full power, or brought power back, hitting their ignition switch and

shutting their engines off.

Propeller damage The Beaver family of aircraft are pushes, this means that the

propeller is found at the rear of the aircraft, thus anything that exist from the

aircraft in flight usually finds its way into the propeller

Items that have been reported

entering the prop are parts of the

exhaust springs and upper and lower

engine cowl screws/washers.

It is suggested that all of the

exhaust springs be SAFETY WIRED

AND THEN FILLED WITH SILICONE.

This will hold the spring together if it fails. Silicone applied to the head of the cowl screws will prevent them from going into the

prop as well.

If your engine is equipped with an aluminum engine cowls these crack around the exhaust and intake manifolds. The fix the

problem replace them with a STEEL COWL. To date I have no reports of the steel

cowl failing.

Another reported item that has entered the prop is the screws and washers holding

the upper and lower cowls together. A dab of silicone over the washer and screws

will prevent this from happening.

Several owners have reported their recoil handles entering the propeller. This

happens when the recoil spring looses its strength. A sign of lost strength is when

the pilot has to tug on the handle several times to get the recoil rope to rewind into

the recoil.

Another area of concern on two place Beavers was the recoil rope guide pulleys. When these fail they cut the recoil rope and it

recoils back into the housing, this of course means the owner now has to prop start the engine!