Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text

ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived

not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

Troubleshooting the Beaver family of ultralight aircraft - fuel system.

UltralightNews.com

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem

Ipsum has been the industry's standard dummy text ever since the 1500s, wn an

unknown printer took a galley of type and scrambled it to make a type specimen book.

It has survived not only five centuries, but also the leap into electronic typesetting,

remaining essentially unchanged.

Beaver, Beaver ultralight aircraft, Beaver RX 35 ultralight

aircraft, Beaver RX 550 ultralight trainer troubleshooting report.

3: The use of inferior oil.

Remember the oil only makes up 2% of the mixture, but without this 2% the engine will not survive. So oils play an important role in

engine life. Note that there are different oils for different engine application. Generally air cooled and water cooled engines do not

use the same oil.

Engines equipped with oil injection are also different than those used for pre-mix. Personal experience shows that many oils used in

the boating industry to cool outboard engines do not work well in Rotax liquid cooled engines. Rotax does have oils that are

produced to their specifications for use in both air and liquid cooled engines.

Beaver Ultralight Aircraft Fuel Tank:

One of the most widely reported problems on all Beavers has been contamination in the fuel tank. This contamination is apparently

the result of deterioration of some of the material and or fittings used in the tank. Owners who have experienced this problem

report that even after a thorough cleaning the problem reappears.

A reported problem on the fuel supply line, retainer bushing assembly on top of the seat tank was that the metal retaining washer

cuts into the side of the fuel line causing an air leak.

Another reported contaminant is water. While most of the seat tanks supplied for

the Beaver have a drain cock at the bottom of the tank, this cock is not at the

lowest point in the tank and its fitting sits about 1/2 an inch off the bottom.

It is recommended that owners remove their tanks on a regular basis, and

thoroughly drain and flush the tank.

Many early model two place Beavers equipped with Rotax 503 engines use a dual

carburetor setup. When supplied from Rotax the engine is set up for use in an

upright engine application (spark plugs facing up).

When used in an inverted installation, like on the early model Beaver ultralight

aircraft, it is recommended that the two aluminum carburetor intake manifolds be

turned over.

Proper installation should have the carburetors at a slight upward angle

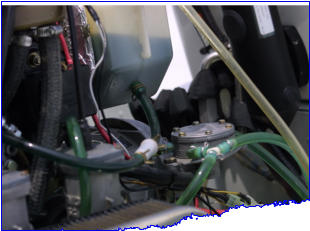

Fuel pump location and mounting were also a problem on Beaver aircraft.

The pump was generally mounted in front of the engine on the guard for the fan.

This mounting is too far away from impulse hole!

All dual carburetor engines should use a DUAL FUEL PUMP, not a single fuel pump

with a "T". On the 503 Rotax SINGLE carburetor engine Rotax is now supplying the

engines with a DUAL PUMP. The two output lines run into a "T" with the one line

then running to the single carburetor.

This an update that should be done to all 503 equipped Rotax engines. The fuel pump

should be mounted ABOVE the impulse hole in the engine with the impulse fitting on

the pump facing DOWN.

The fuel pump should be rubber mounted, away from heat and located not more than

12 inches from the impulse outlet on the engine.

The line used to supply vacuum to the pump should be of a very thick wall (many

Beaver owners have used straight gas line, which is incorrect) so as not to collapse,

and all lines should be securely clamped.

On early model Beavers the carburetor was reported to turn in flight. Later model engines are supplied with knurled intake manifolds

and carburetors which prevent this from happening.