| Within this framework, nail 2"x4"s vertically every 2'. Position them where the 4'x8' chipboard panels overlap, and in the middle of the panels for support. The

chipboard panels should completely overlap the outside of the

4"x4"s. Do not cement the 4"x4"s into the ground until

the hangar walls are finished, and everything is nailed in position and

squared up. Then cement them in, and let it harden before you start to put

the roof on.

At the same time, pour some footers for the trusses to stand

on; make the trusses and cut the roof beams while you are waiting on

the concrete to cure.

The hangar width was determined by the length of

the roofing panels, 18' was the maximum length of the heavy gauge

Strongpanel sections I chose, so the rear wall was sized to allow the

panels to reach almost to the peak, and still stick out 2" over the

eaves.

The peak is covered by a standard pre-bent cap.

The two

outside rear wall sections are 137" wide x 96" high.

The center section is 139" wide x 96" high, and is built and

hung just like the side walls. If you cut out a door section in the back

wall, do not cut through the two bottom 2"x4"s, just plan to

step over them...

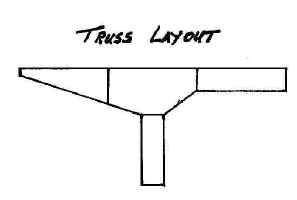

The heart of the hangar is the two cantilever

trusses, which are very simple, and are similar to built-up wing spars,

because they sandwich sections of chipboard between 2"x4"s to

make a very strong structure. The bottom portion is 24" wide and

75" tall. Resting on top of this is the center of the truss, which is

a 4'x8' sheet, with two lower corner triangles cut away.

To cut away the

rear lower corner, starting at the corner, measure out 3', and up 2', draw

a diagonal line, and cut that triangle off. To cut off the front

lower triangle, starting at the corner, measure out 3', and up 1', draw a

diagonal line, and cut that triangle off.

To make the rear end of the

trusses, cut a 4'x8' sheet of chipboard down the middle, making two 2'x8'

sheets. To make the front end of the trusses, cut a 4'x8' sheet on

the diagonal, so that you have two "almost triangles" that

measure 8' on the top side, 3' on the rear side, (the side that butts up

to the middle section of the truss), and instead of coming to a point at

the front of the triangle, you want 8" of vertical depth. Look at the

pictures, it will be obvious. Now box the whole thing in with

2"x4"s on both sides, just like in the pictures, and think ahead

about how you accommodate splicing the 2"x4"s.

Think about

where all the stress lies, and make the 2"x4"s that go up the

lower leg continuous to the top of the truss, have them stop just at the

top horizontal 2"x4"s. Likewise also the 2"x4"s that

run out the front, keep as long as possible to where they tie into the

rear portion . Avoid splicings that are the same on both sides,

stagger the splices.

You will use one sheet of material for two

vertical legs, one sheet for both truss rears, one sheet for both truss

fronts, and two sheets for the truss centers. You will need 26 sheets of

chipboard total for the hangar.

The distance from the front side of the

truss leg to the front of the hangar overhang is 11', this should

accommodate most light planes.

The nose of my Kolb MKIII pokes right up to

the drip line, so I have a heavy tarp that is attached up and inside the

front eave, and is tied down and out to keep water off the nose.

Get

several helpers to set the trusses up, anchor them securely to the rear

wall at the 4"x4", and brace them so they won't lean while you

set the roof beams. Start from the back and work out as you nail the beams

from the walls to the trusses. I made the beams from 2"x6"s ,

from the walls to the trusses, and the center sections of the beams were

2"x4"s from the trusses to the peak.

Sheet metal roofing of

your choice, corrugated barn tin was too light for me. I used Strongpanel,

it cost as much as everything else combined, but I can walk on the roof.

Use light stuff for the front and rear eaves. I did not use gutters, I

wish I had. The splash from the run off is deteriorating the lower edge of

the chipboard. The lower edge of the walls stops about 2" above the

dirt, this allows the air to circulate, and keeps moisture from collecting

even during long humid spells. The leaves blow under and in, but leaves

don't corrode the airplane...

The floor is covered with sheet

plastic, and then covered with used carpet. Find someone that is re

carpeting, and get the sections intact, if possible.

The outer front

walls will tend to flex unless they are triangulated. Cement a length of

steel rod in the ground about 1' out from the corner, and run some flying

wire from there up to the top corner of the wall, turnbuckle it snug,

stops the flex.

The roof doesn't have too much pitch, Tennessee

never has more than 24" of snow at a time, and I can clean it off

faster than it comes down most of the time. The roof may need more pitch

farther North. I have a couple posts sized to brace up under the front of

the trusses whenever I am expecting heavy snow anyway.

The Hangar

Courtesy of Richard Pike

rpike@preferred.com

|