Quad City

Challenger heater, in cabin heater for Challenger, ultralight

aircraft heater, heater for the Challenger ultralight.

|

|

|

|

The World's first Lightsport and Ultralight

Aircraft weekly web video webcast!

If you have high speed internet and Windows Media Player

installed you can watch our weekly Light Sport and

Ultralight aircraft webcast!

Each issue is 25 to 35 minutes in length and

is live on the web for 7 days.

Click here for more information! |

|

|

|

|

|

|

|

|

Click here for this months specials! |

|

|

|

|

|

|

|

Click

HERE to

receive ULTRALIGHT NEWS EXTRA!

Our monthly newsletter

packed full of information about ultralight aviation!

|

|

How to get heat from your Rotax air-cooled engine.

|

|

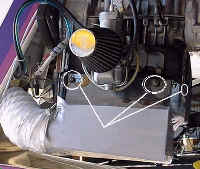

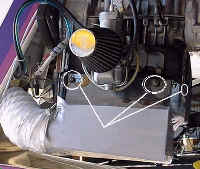

AP-BIW* heater unit for

Challenger *AP-BIW = AIN'T PRETTY BUT IT

WORKS AP-BIW* heater unit for

Challenger *AP-BIW = AIN'T PRETTY BUT IT

WORKSHere's a side view

showing the three existing Rotax cover screws that were used to secure the

plastic (lexan) heat collector.

The entire box is made of

scrap lexan that was cut out with scissors. |

|

Most of it is actually a single piece, bent along the lines to form the right angles, then taped with SNOWBOARD REPAIR TAPE to strengthen the bends. Most of it is actually a single piece, bent along the lines to form the right angles, then taped with SNOWBOARD REPAIR TAPE to strengthen the bends.

Snowboard repair tape is a thick, clear tape

that is incredibly pliable even in very cold weather and is very

sticky. I think it's fantastic. I bought a role of it that was

a foot wide, so I can cut it any way I want to.

View from

rear. Back is attached only by one screw.

The larger picture

(click the little one) shows better where I've used one of the head bolts

to attach the heater in the area of the spark plugs.

I taped only the bottom portion of the

heat collector because I was too anxious to go flying and, besides, taping

clear lexan is boring. |

Looking up from

front area. Just another view showing where the side of the

collector is attached to the Rotax using two of the existing motor cover

screws.

The cheapy dryer hose is both clamped and taped

to the lexan box. I formed a cylinder from a separate piece of lexan

as a hose attachment and then taped it to the open end of the collector

box with some of that snowboard tape.

Actually, most of Cloud Dancer is held together

with it. Just kidding. |

|

Click on pictures for larger view!

|

The cheapy dryer

duct hose enters the cockpit here. I cut out a half-moon shaped

opening in the aluminum sheet and applied a strip of vinyl edging . . .

the type you buy to protect car door edges. The cheapy dryer

duct hose enters the cockpit here. I cut out a half-moon shaped

opening in the aluminum sheet and applied a strip of vinyl edging . . .

the type you buy to protect car door edges.

This keeps

vibration from allowing the aluminum to cut through the plastic

hose. There was just enough room here for the ducting

to enter alongside all the wiring and the fuel lines. |

Doesn't look like

it, but there's plenty of room to pull the dryer hose up past the seat and

suspend it where it will be positioned between your legs. Doesn't look like

it, but there's plenty of room to pull the dryer hose up past the seat and

suspend it where it will be positioned between your legs.

The stick

has full clearance because the flexible hose is, well, flexible. It

moves an inch or two either way, or back and forth, as the stick

moves.

This makes for comfy feetsies and the heat seems

to build in the cockpit better when it moves from the front to the

back. With both doors on, my CI gets

cozy!

|

|

|

|

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28

Index for this section. |

|

|

|

|

|

|

|

|

|

Ultralight Aircraft News Web Magazine Covering the World of Ultralight Aviation .

You may link to these pages or print

them out for your own personal use, but no part of this

publication may be copied or distributed, transmitted, transcribed,

stored in a retrieval system, or translated into any human or computer

language, in any form or by any means, electronic, mechanical,

manual, or otherwise, without the written permission of Ultralight News.

By copying or paraphrasing the intellectual

property on this site, you're automatically signing a binding contract

and agreeing to be billed $10,000 payable immediately. Copyright Ultralight News

|