Quicksilver MX airframe troubleshooting reports

QUICKSILVER MX TAIL BRACE AND CHANNEL BRACKET WEAR - Another area of reported wear is in the tail brace tube (40440). The wear can be found in both the channel bracket and tube, at both ends, where the tube rests in the channel bracket.

A simple solution to this is to install small plastic washers on both sides of the tube, between the tube and channel bracket. This makes the wear part the plastic spacer rather than the tube and bracket.

QUICKSILVER SEAT SUPPORT BRACKET FAILURE

The "U" shaped tube used to support the seat, located directly below the seat, (seat mount assembly), was reported to fail (in early model MX's,) at the point where the bolts go through to attach the seat belts, and seat, to the "U" bracket.

Later models were strengthened in this area.

SEAT BREAKAGE

Another problem reported was the breaking of the seat, at its base. This was caused by pilots restraining their aircraft during run up, while seated in the craft, and applying pressure to the back of the seat to prevent the craft from moving.

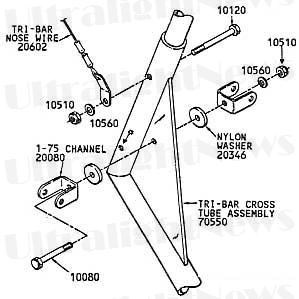

QUICKSILVER MX TRIBAR CROSS TUBE ASSEMBLY - On the tribar cross tube are located four channel brackets used to connect the nose struts and axle struts to the assembly. Numerous pilots have reported the bending of the flat plate which the channel brackets and flat saddles bolt to, again caused by hard landings, usually by the nose wheel hitting first.

The bolts used to connect these groups of brackets and saddles has also been reported to bend and it is suggested that it be an area of regular inspection.

It was also noted during the disassembly and reassembly of a damaged MX that the TRI BAR CROSS TUBE ASSEMBLY WAS BENT. This could only be noted by complete disassembly, and the laying of the unit on a flat surface.

It was also noted prior to disassembly that the craft required considerable pilot input to fly straight and level, while after replacement of the assembly with a new unit it again flew as an MX should.

REAR DOWN TUBES

The rear downtubes on the MX have been reported to show elongation of the holes where the top of tube fastens to the root tube. This elongation is generally not visible unless the pilot removes the down tubes and examines in behind the plastic saddle, which acts as a stand off from the root tube.

Another wear point on the rear downtubes is on the tubes inner sides. This wear is caused by the two tubes contacting the driveshaft coupler, or coupler bolt.

Also if the pilot has updated to the flex drive coupler it is necessary to reposition the rear downtubes in such a way as to clear the coupler. (For more info contact a parts depot or service centre).