Rotax 532, Rotax 582 Liquid Cooled Aircraft Engine Troubleshooting.

Return To Ultralight News Main Index

This report will deal with problems associated with the use of the liquid cooled 532 and 582 cc Rotax engines.

Areas to be covered: Recoil, Electric Starter, Cooling system, Gear drive, Fuel system, Exhaust system, Ignition system. Cold Seizure. Engine Top End.

Recoil

Several problems have been reported in the with the recoil system on the 532 Rotax engine. The most widely reported is the cracking and eventual breaking of the outer housing.

This breakage first appears as a hair line crack in a circular area about 4 inches in diameter, in the center of the housing. This crack if not repaired or the recoil housing replaced, will cause the housing to completely break away. The loose parts may then fall into the magneto, or starter cup causing damage to the engine, or engine failure. Pilots have reported being able to weld the crack, the recommended solution is the replacement of the outer housing. Part # 910 107.

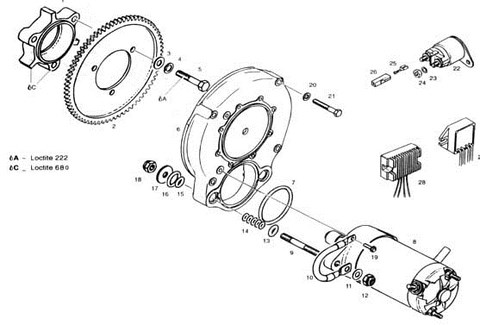

Another reported problem in the recoil assembly of the 532 is the disintegration of the starting cup (part # 852 322). This part is attached to the magneto with three bolts, and is located directly behind the recoil starter.

Prior to the disintegration of this cup pilots have reported hearing an unusual noise coming from their engine, then complete loss of engine power. The loss of power is caused in most cases by the parts and pieces of the cup, jamming between the block halves and the magneto, locking up the crankshaft.

It is suggested the pilots check this area on a regular basis, and at the first sign of cracks or deteriorating replace the cup.

CAUTION: When ordering parts, specifically request GENUINE ROTAX PARTS, infield inspection has shown that some supply houses are providing inferior parts, or parts that are not exactly the same size or strength as that of genuine supplied by Rotax.

Electric start

Several electric starters are available for the Rotax 532/582 engine. The only one that I recommend is Rotax supplied starter.

The starter should be used with a minimum 20 amp hour battery. The battery leads should be no more than 5 feet in length. and a separate ground cable must be run to the engine, to ensure proper ground.

Several owners have reported burning up their engine wiring system when they failed to follow instructions and properly ground the engine. This is caused by the single small ground wire that is grounded to the coil mounting bolts, melting in the wiring harness, fusing wires together when the engine is cranked. This wire is not large enough to carry the kind of current necessary.

When using an electric start on a Rotax aircraft engine TWO grounds are required, one going from the engine to the airframe and another going from the engine to the negative side of the battery. These ground cables should be about the same diameter as that used on a GOOD set of booster cables, that you would use to jump start your car. (In many cases that is what pilots have used).

Other pilots have reported failure of the starter solenoid supplied with the Rotax starter. It would appear that this failure is caused by improper mounting of the solenoid. The solenoid should be mounted in free air away from vibrations, and as close to the engine as possible.

I don't even recommend using the solenoid that is USUALLY supplied with the starter from Rotax. Instead drop into your local Canadian Tire store or a good automotive supply center and get a solenoid for a Ford car, or truck. It can usually be found on the fender. I have never had one of these fail and it can be purchased locally.

Another reported problem with the starter is the failure of the studs used to secure the starter to the ring gear housing. If your starter is mounted in any position other than the 6 o'clock position failure of the stud will result in the two big washers found on the end of the stud to fall into the magneto. The washers are then picked up by the magnets with catastrophic results. Usually destroying the crankcases and ignition system.

To help prevent this it is suggested that the starter only be mounted in the six o'clock position. If the studs break in this position the washers would fall harmlessly to the ground. However I also suggest that you run a bead of silicone from one end of each stud to the other end, including over the casing. This way if the stud fails you still have the washers, and ALL of the little rubber shock absorbers that are on the studs [about $60 worth of parts].