http://www.ultralightnews.ca/ Page 22 of 30

The Ultralight News - your one stop Ultralight News.

8.Replacement of Parts

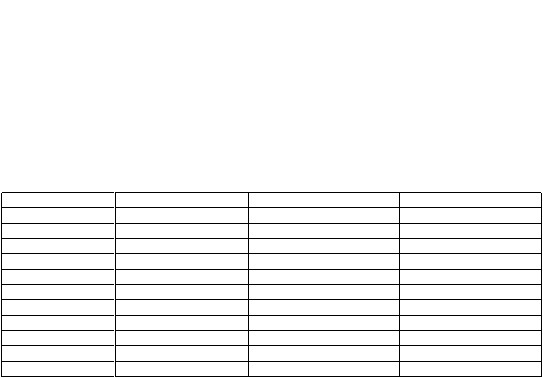

The parts listed in Table 3.3-1 should be replaced after the specified number of operating hours.

Consideration should be given to componets which may show signs of premature failure and replaced

accordingly.

Table 7-3-1

The abbreviation ?Single? means single ignition and ?Dual? represents dual ignition.

Number Designation Order number Operating Hours

2

Sparkplug Single 023.29 50

4

Sparkplug Dual 023.28 50

2

Sparkplug cap 024.22 100

4

Sparkplug cap 024.22 100

2

Piston set 014.78 1000

1

Crankshaft 271 AC1U 1000

2

Cylinder Head Single 322 A3 + 322 B2 1000

2

Cylinder head Dual 272 AW2+272 AW3 1000

2

Cylinder 272 AL1 1000

2

Carburettors Bing 54/38/141 1000

2

Air filter 066.16 100

8.1.Maintenance instructions - Carburettors

The Bing carburettor jets are jetted by the manufacturer so the engine is guaranteed to run thermally secure.

Tampering with the jet systems of the carburettors can lead to overheating and damage to the motor and

should be avoided. Only original replacement parts should be used. Information concerning the carburettor

assembly may be obtained from AATI Pty Ltd or your Hirth distributor. Should any parts be required, the

carburettor specification should be quoted. This is identified on the side of the carburettor intake (?/?).

8.2.Synchronisation of dual Bing carburettors

In order to ensure performance and smooth running of the engine, the two carburettors must be synchronised

precisely. Note that the idle adjustment screw holds the slide in the same position on both carburettors.

Measure and adjust the opening height on both carburettors for this. The two cables which move the slide in

the carburettor usually come together in a Y fitting leading to a single throttle cable. The cables between the

Yfitting and the carburettors need to be adjusted so that there is some play in the cable at the idle position.

This will insure the proper idle position of the slides. When the throttle cable is pulled, the slides of the

carburettors should move upward simultaneously from the idle position. Lubricate cables if difficult to

operate. Defective or frayed cables have to be exchanged for new ones immediately. Bent cable must be

changed immediately.

8.3.The basic setting of the mixture regulating screw

The idle mix regulating screw in the basic setting is opened half a turn in both carburettors. To do this, screw

the idle mix regulating screw lightly in towards the stop, then open half a turn.

8.4.Cleaning of the carburettors

Turn off the fuel valve before cleaning carburettors. Open the spring clip which holds the float chamber

against the carburettor. Move float chamber downward carefully since it is filled with fuel. Remove the fuel

from float chamber along with any debris. Should debris be in float chamber, the fuel filter in the intake line

between tank and fuel pump should be checked and, if necessary, replaced.

Pull plastic strainer from around the mixing tube and, if necessary, clean with fuel. Screw out the main jet

from the mixing tube and check for damage or grime. Replace immediately if damaged; clean with gasoline if